Products

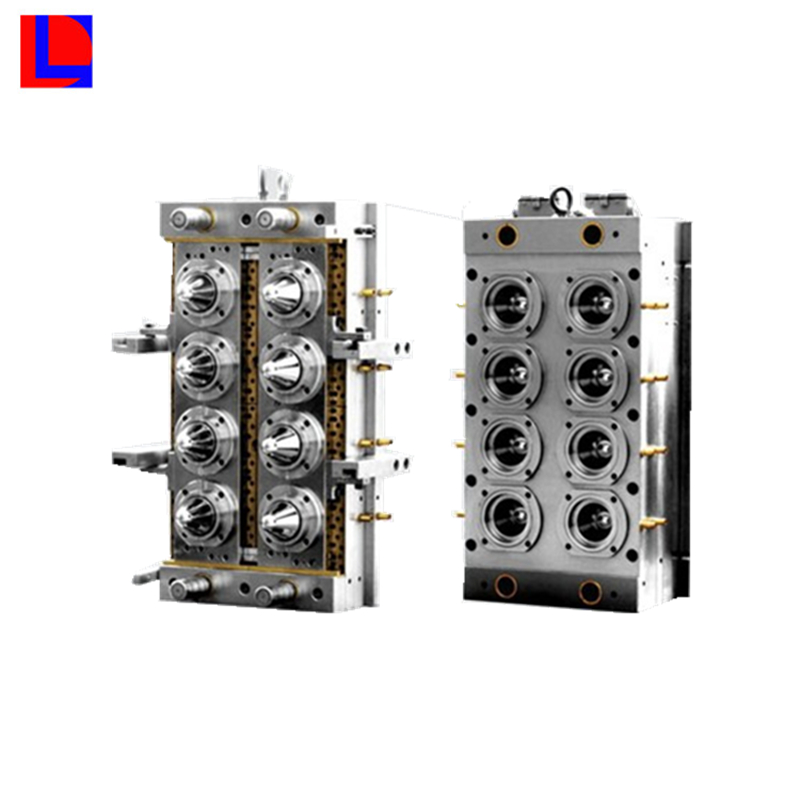

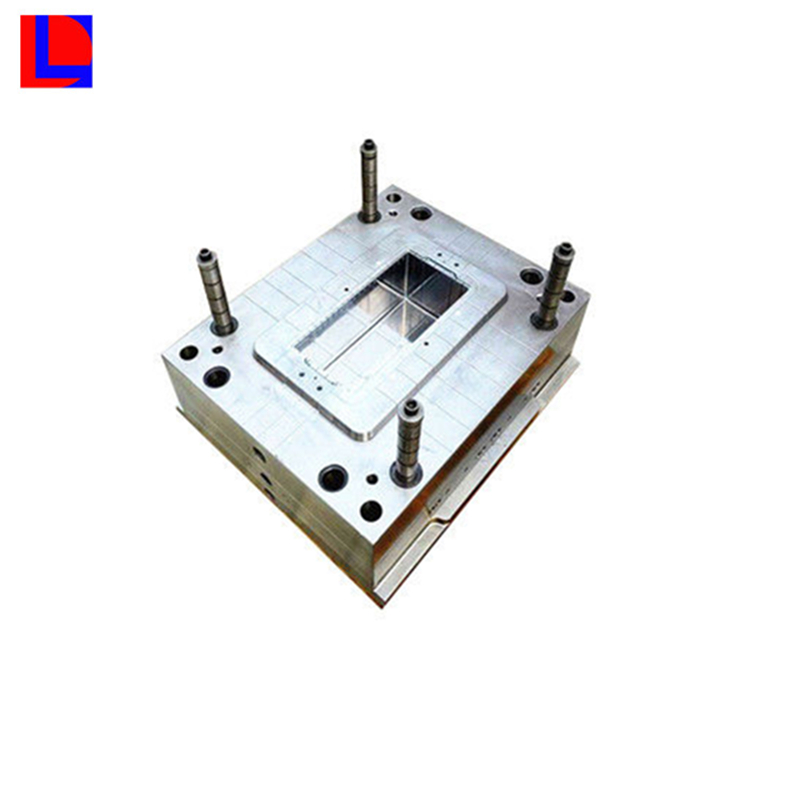

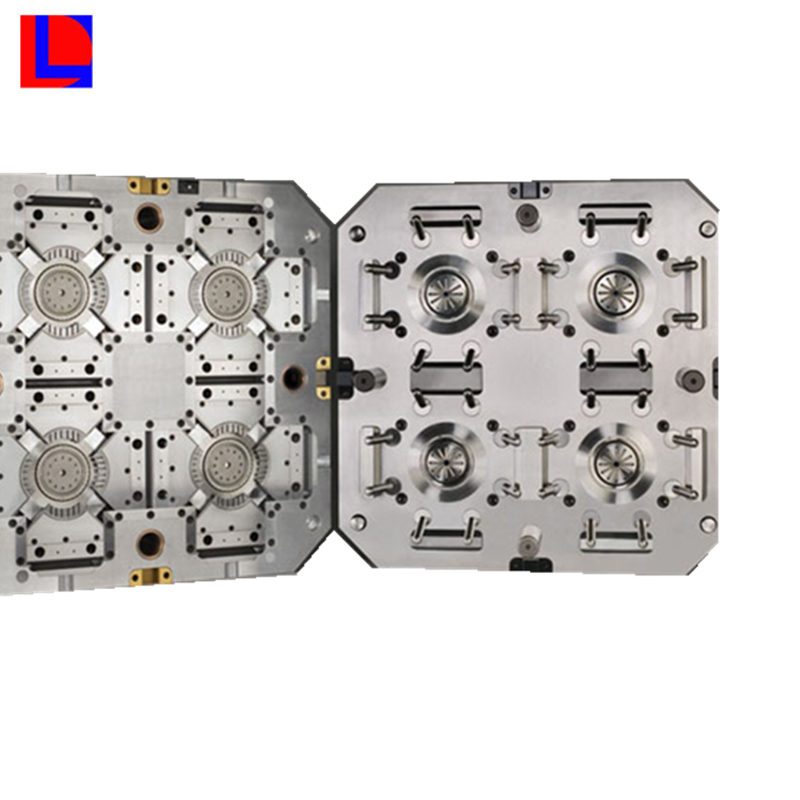

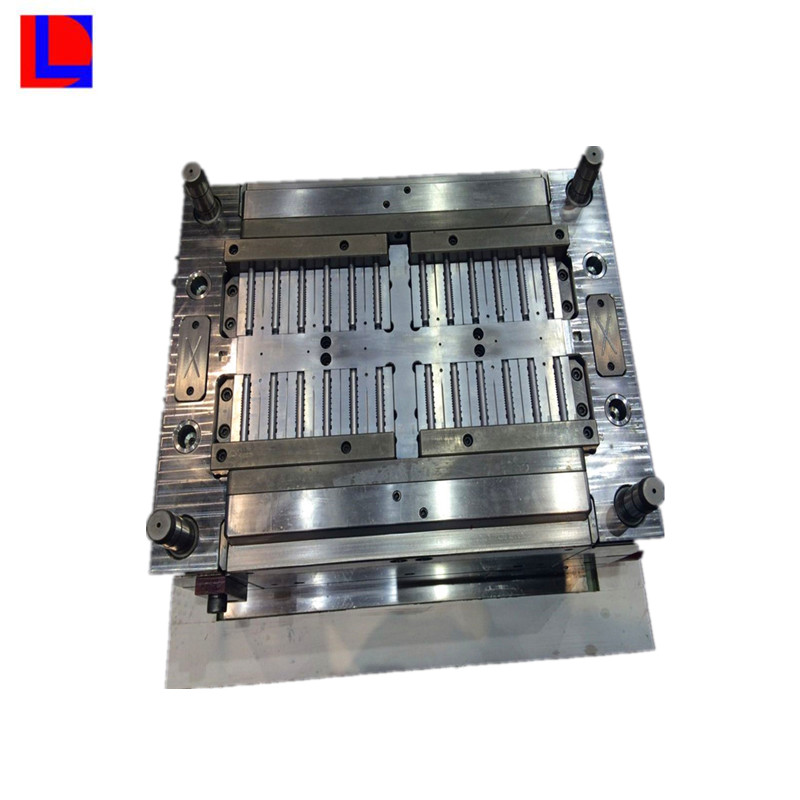

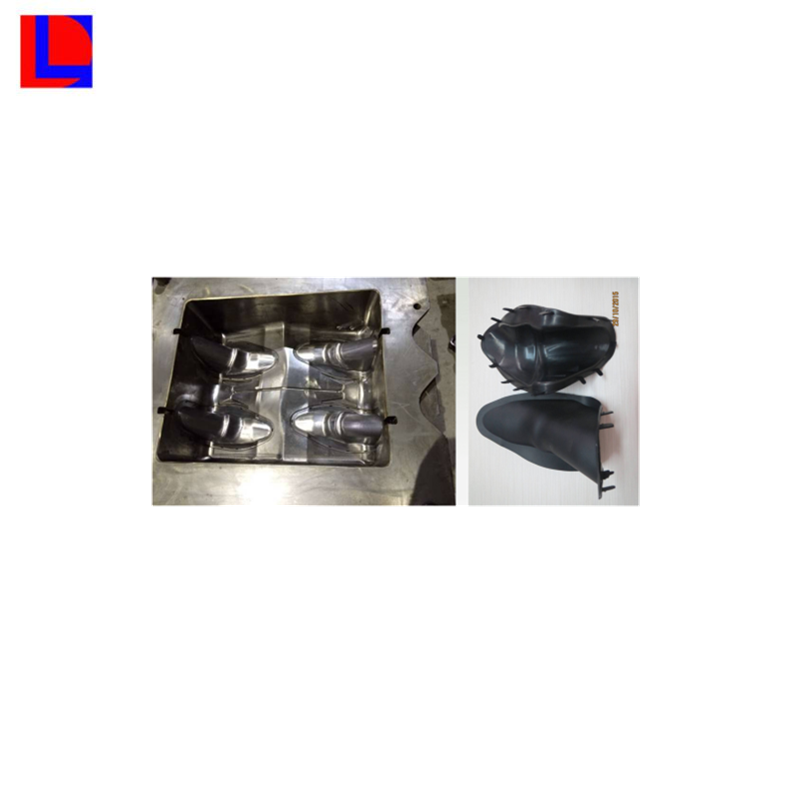

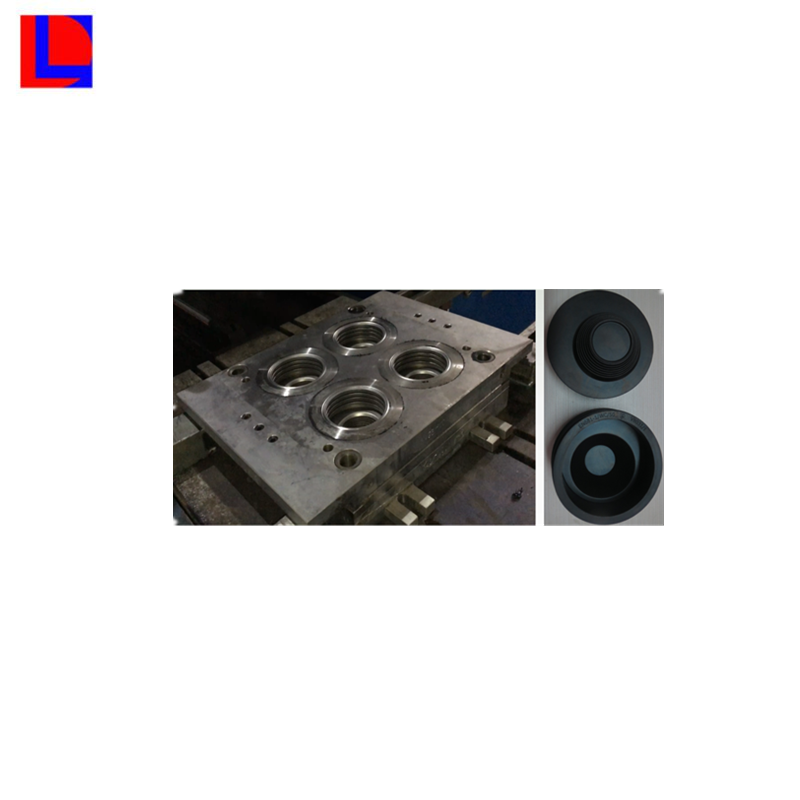

High Quality Silicone Rubber o-ring Mould/Prototype Mold Making for o ring manufacturing process

Five Advantages Of Products

- OEM&ODM service of kinds of moulds and products.

- We sign confidential agreements with all our OEM&ODM customers.

- Reasonable price and Good after-sales service

- Established in 2003,specializes in the research and development all kinds of moulds.

- Our qualified and professional foreign trade team will help you to keep the delivery date on time.

Product Details

Product Detail:

Place of Origin:Fujian, China (Mainland)

Color:Various

Mould life:According to your requirement

Cavity:Single/Family,as request

Size:As per customer's design

Sample:15 days

Tooling machine:CNC , EDM , Engraving ,Wire-Cutting

Quality:SuperiorPart

Mold technical: Injection or compression

Mould Components:EDM standard

Mould Material:45#, P20, H13, 718, 2738, NAK80, S136 etc.

Rubber Material:NBR,NR,EPDM,SILICONE,FKM, ect.

The mold’s producing processes:

Order → Designer confirm → Design 3D drawing (or provided by customer) → Processing raw

material → Rough machining → Primary assembly → Assembly confirmation → Rough polishing

→ Heat treatment → Precise polishing → Finally assemble → Quality control → Delivery

Why choose us

1. Manufacturing and exporting experience since 2003 . ISO 9001&TS16949 approved.

2. Products are supplied to over 50 countries.

3. One-stop service from rubber molded parts to rubber extruded parts. Save time and save money for you.

4. In-house mold design and building capabilities

5. Injection, injection transfer, compression, extrusion and silicone liquid injection capabilities

6. Our product are in high quality

a)No reclaimed rubber used to ensure quality.

b) Auto rubber milling production line.

c) Complete in-house custom compound formulating and mixing.

4) Rubber compound is tested before production

7. Rubber compound can be RoHs, Reach, FDA approved. Other certificates can be done according to different customer's demands

8. Strong advantage for auto rubber part. PPAP, MSDS, IMDS available.

9. Keep secret to your idea and your design.

10. 24 hours (two shifts) / 6 days for production.

11. Professional design team, mold maker engineer. OEM/ODM service.

12. Professional QC and R&D teams to assure high quality

13. Professional sales team. Good English capabilities and communication skills.

14. No MOQ

15. Prompt delivery. For prototype: 3-7 days, Production orders can be arranged specially to meet customer’s urgent demands

16. Geographical advantages: within 30 minutes to airport or sea port.

XIAMEN LINDAS HARDWARE INDUSTRICAL CO .LTD

Contact Person: Teeny Cai

Telephone: +86 18060919930

Landline: +86 592-5505655

Company Address: A-916,Lianfa Electronic Market,802 Yuanshan South Road,Xiamen 361009,China

Website: lindasmould.us764.com

Previous: OEM ODM Small Plastic Mold High P...

-

Customized service china factory supplier mold plastic

-

High quality for plastic part customized molding producer...

-

Molding design OEM factory plastic customized molding

-

China manufacture plastic molding supplier custom mold pl...

-

High quality customized rubber mould injection moulds com...

-

Xiamen Factory Directly Sells OEM rubber Injection Mould ...

-

Chinese mould manufacture provide injection moulds with r...

-

China Professional mould maker compression moulds for mou...